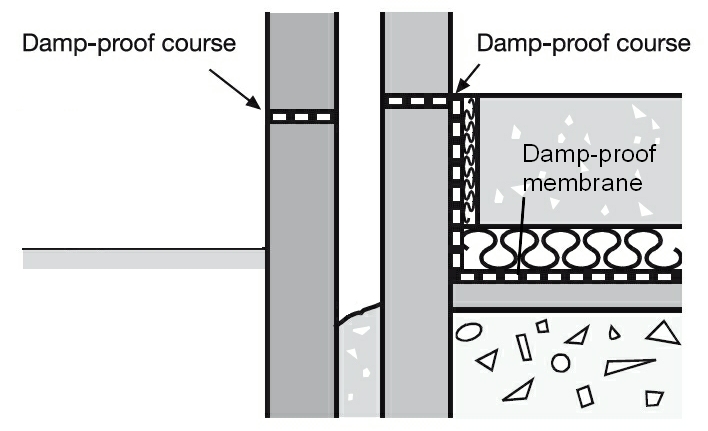

DPC (Damp Proof Course) is a construction term referring to a layer or barrier installed in buildings to prevent moisture or dampness from rising through walls or floors. Typically made of materials like bitumen or plastic, DPC serves as a protective measure against potential water damage.

On the other hand, DPM (Damp Proof Membrane) is another construction term related to moisture control. DPM is a thicker membrane, often made of materials like polyethylene and is primarily used beneath concrete floors to prevent moisture from seeping through. It acts as a strong barrier against ground moisture, enhancing the longevity of the structure.

Which Materials Are Used In Dpc?

Various materials are used in Damp Proof Course (DPC) installations, each selected for its specific properties and suitability in preventing the infiltration of moisture. Common materials include

Bitumen-Based Materials

Bitumen, a viscous and waterproof material derived from crude oil, is often used in the form of bituminous felt or bitumen sheets. Bitumen-based DPC materials exhibit excellent moisture resistance and durability, making them suitable for preventing rising damp.

Polyethylene (Plastic) Membranes

DPC membranes made from polyethylene, a flexible and thermoplastic polymer, are widely used. These plastic membranes are known for their flexibility, durability, and effective resistance against moisture penetration.

Metal Sheets

In specific situations, metal sheets, such as lead or copper, may be used as a DPC material. Metal sheets provide a strong barrier against rising damp and offer strength and resilience in certain applications.

Rubberized Asphalt

DPC materials may include rubberized asphalt, a blend of asphalt and rubber compounds. Rubberized asphalt combines the waterproofing properties of asphalt with the flexibility of rubber, creating an effective moisture-resistant barrier.

PVC (Polyvinyl Chloride)

PVC, a synthetic plastic polymer, is used to manufacture DPC membranes. PVC DPC materials are known for their durability, resistance to chemical degradation, and flexibility, making them suitable for diverse construction scenarios.

Cementitious Compounds

Cement-based compounds can be utilized as DPC materials, often in the form of cement mortar. Cementitious DPC provides a dense and resistant layer against rising damp, especially in masonry applications.

Flexible Mortar

Flexible mortar, containing polymers or additives to enhance flexibility, is employed in some DPC applications. This type of mortar adapts well to movement in the building structure while maintaining its damp-proofing characteristics.

Which Materials Are Used In DPM?

Damp Proof Membrane (DPM) materials are selected based on their ability to create a barrier against moisture, especially beneath concrete floors. Common materials used in DPM installations include

Polyethylene Sheeting

Polyethylene is a versatile thermoplastic polymer, and DPM often comes in the form of polyethylene sheets. Polyethylene provides an effective barrier against ground moisture due to its impermeability and flexibility.

Polyvinyl Chloride (PVC):

PVC, a synthetic plastic polymer, is used to manufacture DPM membranes. PVC DPM materials offer durability, chemical resistance, and flexibility, making them suitable for use in diverse construction environments.

Bitumen-Based Membranes

Bitumen, derived from crude oil, is used in the form of bituminous membranes for DPM applications.

Bitumen-based DPM membranes are known for their waterproofing capabilities and resistance to ground moisture.

Butyl Rubber

DPM materials may include butyl rubber, a synthetic rubber with excellent impermeability. Butyl rubber provides a robust and flexible membrane that effectively prevents the ingress of moisture.

EPDM (Ethylene Propylene Diene Monomer)

EPDM is a synthetic rubber commonly used in the construction industry, including DPM applications.

EPDM exhibits excellent durability, elasticity, and resistance to weathering, offering reliable protection against ground moisture.

Cementitious Coatings

Cement-based coatings, often containing additives for flexibility, are applied as DPM in some scenarios.

Cementitious DPM coatings provide a dense and resistant layer that acts as an effective barrier against ground moisture.

Composite Materials:

Composite DPM materials may combine different layers or materials, such as polyethylene and bitumen, to enhance overall performance.

Composite DPM materials leverage the strengths of multiple components to provide a comprehensive moisture barrier.

HDPE (High-Density Polyethylene)

HDPE is a type of polyethylene with a high density, and it is used in the manufacturing of DPM materials.

HDPE offers a high level of impermeability, durability, and resistance to chemical degradation, making it suitable for DPM applications.

Where Should You Install Damp Proof Course (DPC) and Damp Proof Membrane (DPM)?

| Installation Locations | Damp Proof Course (DPC) | Damp Proof Membrane (DPM) |

| Underground Floors | At the base of walls, above ground level. | Directly beneath ground-level floors. |

| Basement Walls | Integrated into the thickness of walls. | Applied against basement walls. |

| Crawl Spaces | In cavity walls, especially in cavity wall constructions. | Beneath buildings in crawl spaces. |

| Concrete Slabs | Integrated into the structure of solid walls. | Beneath concrete slabs, especially in ground-floor constructions. |

| Retaining Walls | Installed at the base of walls, typically above ground level. | Often used in retaining walls. |

| Roof Terraces | Integrated into lintels and below sills. | Used in the construction of roof terraces. |

| Planter Boxes | Incorporated into the thickness of walls. | Applied in planter boxes. |

| Paved Areas | Installed beneath the cavity of double-walled structures. | Beneath paved surfaces. |

| Foundations | Installed into lintels and sills. | Crucial in foundation construction. |

| Landscaping Applications | In cavity walls, especially in cavity wall constructions. | Used in landscaping applications to prevent water penetration into structures. |

| Tanking Systems | In the thickness of walls, especially in cavity wall constructions. | Integrated into tanking systems for below-ground structures. |

| Renovations and Extensions | Integrated into lintels and below sills. | Applied in new extensions or during renovations. |

When is DPC Installation Necessary?

The installation of Damp Proof Course (DPC) is necessary in various scenarios to address and prevent rising damp issues.

Older Buildings without DPC

Many older buildings were constructed without an effective DPC. Retrofitting a DPC is often necessary to prevent or mitigate rising damp in these structures.

Renovations and Extensions

When renovating or extending a building, especially in areas prone to dampness. Integrating DPC during renovations ensures that the new or extended sections are adequately protected against rising damp.

Deterioration of Existing DPC

Over time, DPC materials can deteriorate, compromising their effectiveness. Replacing or reinforcing the existing DPC becomes essential to maintain its damp-proofing capabilities.

Change in Ground Level

Alterations to the ground level around the building, such as landscaping or the addition of new structures. Changes in ground level can disrupt existing DPC or expose lower sections of walls to increased moisture, necessitating the installation of DPC.

Insufficient DPC during Construction

Errors or oversights during the initial construction phase may lead to the absence or inadequacy of DPC. Addressing the oversight by installing a proper DPC is essential to prevent rising damp issues.

High Rainfall or Coastal Locations

Buildings located in areas with high rainfall or coastal regions where moisture levels are elevated. Increased moisture levels in these environments heighten the risk of rising damp, making DPC installation imperative.

Change in Building Use

When the function or use of a building changes, leading to different moisture conditions. Adapting the building for a new purpose may require reevaluating and installing an appropriate DPC to match the altered conditions.

Historic Preservation:

Preserving historic structures that may lack modern damp-proofing measures. Installing a discreet DPC while preserving the historic integrity of the building helps prevent moisture-related damage.

Preventive Measures in New Construction:

Designing and constructing new buildings in damp-prone areas. Incorporating DPC as a preventive measure in the initial construction phase ensures protection against potential rising damp.

When is Damp Proof Membrane (DPM) Essential in Construction?

Below Ground Flooring

- In constructions with ground-level floors susceptible to moisture.

- Essential to prevent ground moisture from infiltrating and affecting flooring materials, ensuring a dry and durable foundation.

Basement Constructions

- When building structures with basements or below-ground levels.

- Crucial to shield basements from the impact of ground moisture, preventing potential water penetration and associated issues.

Crawl Spaces and Foundations

- In constructions featuring crawl spaces beneath buildings and foundation elements.

- Necessary to create a protective barrier, guarding against moisture-related damage to foundational components.

Retaining Walls

- Construction of retaining walls to hold back soil.

- Essential for preventing water seepage into the retained soil, preserving the structural integrity of the retaining wall.

Roof Terraces and Balconies

- Building roof terraces or balconies.

- Important to protect underlying structures from water infiltration, ensuring longevity and minimizing potential damage.

Planter Boxes and Landscaping

- Incorporating planter boxes and landscaping features.

- Necessary to prevent soil moisture from affecting adjacent structures and landscaping elements.

Paved Surfaces and Driveways

- Construction of paved surfaces, driveways, and walkways.

- Essential beneath these surfaces to act as a moisture barrier, preserving the integrity of the paving and preventing ground moisture penetration.

Renovations and Extensions

- During renovations or extensions to existing structures.

- Vital to ensure that new additions or renovated areas are adequately protected against potential ground moisture issues.

Waterlogged or High Water Table Areas

- Building in regions prone to waterlogging or with a high water table.

- Essential to counteract the heightened risk of ground moisture, providing a crucial layer of protection.

Tanking Systems for Below-Ground Structures

- Integration of tanking systems in below-ground constructions.

- An integral component of tanking systems, preventing water ingress and contributing to comprehensive waterproofing.

How Does Damp Proof Course (DPC) Work to Safeguard Against Rising Damp?

Damp Proof Course (DPC) operates as a vital component in the battle against rising damp, playing a multifaceted role in maintaining the structural integrity and longevity of a building.

Barrier Against Capillary Action: DPC acts as an unwavering barrier, staunchly opposing capillary action – the phenomenon where moisture ascends through porous building materials. By disrupting this upward movement, DPC effectively halts the progression of rising damp.

Interrupting Moisture Path: Strategically positioned during construction, DPC serves as a strategic interruption to the path of moisture. Placed at vulnerable points, it prevents water from infiltrating walls and floors, safeguarding against the potential consequences of rising damp.

Preserving Structural Integrity: At its core, the primary function of DPC is to preserve the structural integrity of the building. By impeding the upward flow of dampness, it shields load-bearing and non-load-bearing walls alike from the damaging effects of moisture.

Preventing Decay and Deterioration: Damp conditions can trigger the decay and deterioration of building materials, compromising the strength and durability of the structure. DPC acts as a stalwart defender, preventing these detrimental effects and ensuring the robustness of the construction.

Mold and Fungus Prevention: Beyond structural concerns, rising damp creates an environment conducive to the growth of mold and fungus. DPC, by curbing the upward migration of moisture, plays a pivotal role in minimizing these conditions. This not only protects the building but also contributes to a healthier indoor atmosphere.

Enhancing Longevity: DPC significantly contributes to the longevity of a building. By effectively countering rising damp, it mitigates the potential for long-term damage, reinforcing the structure’s resilience against the challenges posed by moisture infiltration.

How Does Damp Proof Membrane (DPM) Protect Your Building Against Ground Moisture?

Damp Proof Membrane (DPM) stands as a formidable defense against the encroachment of ground moisture, offering a range of functionalities crucial for preserving the integrity and longevity of a building.

Impermeable Barrier: At its core, DPM acts as an impermeable barrier, forming a powerful shield against the infiltration of ground moisture. This impermeability is vital in creating a dry and secure environment within the building.

Preservation of Structural Elements: By positioning DPM beneath ground-level floors, this protective layer becomes instrumental in preserving the structural elements of the building. It acts as a stalwart defender, preventing moisture-related damage that could compromise the stability of the structure.

Mitigation of Rising Damp: One of the primary functions of DPM is to mitigate the risk of rising damp. By hindering the upward movement of ground moisture, DPM plays a pivotal role in preventing potential damage to walls and floors, ensuring the building remains resilient over time.

Enhanced Longevity: DPM significantly contributes to the enhanced longevity of a structure. By serving as a barrier against the corrosive effects of ground moisture, it safeguards building materials, supporting the overall durability and lifespan of the construction.

Prevention of Mold and Mildew: Beyond structural concerns, DPM plays a crucial role in fostering a healthier indoor environment by preventing the conditions conducive to mold and mildew growth. The effective moisture barrier created by DPM contributes to the overall well-being of the occupants.

FAQ

How to connect DPM to DPC?

Connecting DPM to DPC is simple! Just ensure a seamless overlap, creating a tight seal. Think of it like putting together pieces of a puzzle for effective moisture protection.

What thickness is DPM?

The thickness of DPM (Damp Proof Membrane) varies, but it’s commonly around 0.2mm to 0.5mm. This ensures a sturdy barrier against moisture, keeping your space dry and secure.

Why is DPM important?

DPM is crucial as it acts like a shield, preventing moisture from seeping into buildings. It’s like armor for your structure, keeping it safe from the damaging effects of dampness.

Why do we need DPM and DPC?

DPM (Damp Proof Membrane) and DPC (Damp Proof Course) are tag-team champions against moisture. DPM keeps surfaces dry, while DPC prevents rising damp. Together, they create an unbeatable defense for your building.

What is the best DPM?

The best DPM is one that suits your specific needs. Look for a high-quality membrane with the right thickness for your project. Popular choices include polyethylene and bitumen-based membranes.

What is the function of DPC?

DPC, or Damp Proof Course, acts as a barrier to rising damp. It’s like a moisture bouncer, making sure water doesn’t climb up your walls and cause trouble. Think of it as your building’s waterproof superhero!

Where is DPM used?

DPM finds its home in various places, from basements to ground floors. It’s a go-to solution in construction to keep buildings dry and resilient against moisture, ensuring longevity and structural integrity.

How thick is damp proofing?

The thickness of damp proofing can range, but a common thickness is around 2mm to 4mm. This thickness forms a robust defense, preventing water infiltration and safeguarding your structure.

What is the thickness of DPC?

DPC thickness typically hovers around 150mm to 450mm, depending on the specific requirements of your construction. This ensures that rising damp doesn’t stand a chance, keeping your walls dry and steadfast.

Final words

In conclusion, understanding the difference between Damp Proof Course (DPC) and Damp Proof Membrane (DPM) is vital for effective moisture management in construction. While DPC guards against rising damp in walls, DPM serves as a barrier against ground moisture affecting floors. Their distinct applications highlight their complementary roles in preserving the structural integrity of buildings.

Whether preventing moisture from below or above, choosing the right damp-proofing solution ensures a durable and resilient construction. So, next time you embark on a building project, consider these differences to make informed decisions for a moisture-free and long-lasting structure.